Excel template for inventory management

Votez ce document: ☆☆☆☆☆★★★★★

Excel template for inventory management

Aplikasi stok barang sederhana excel adalah perangkat sederhana untuk memonitor persediaan barang dagang. Hai saya sudah mencoba untuk menggunakan aplikasi excel persedian barang versi satu ini saya boleh dibantu untuk ganti tahun nyaa menjadi 2019. Pengertian dan contoh laporan stock opname excel. Sheet laporan terdiri dari kolom. We tried to find some amazing references about Stock Report Format In Excel Free Download And Stock Analysis Template Excel 2016 for you. It was coming from reputable online resource which we like it. We hope you can find what you need here. We constantly attempt to reveal a picture with high resolution or with perfect images. Download Microsoft Excel 2010: Interactive menu to ribbon guide from Official. Laporan stock opname merupakan hasil dari stock opname yang telah dilakukan. Stock maintain template holds great importance in different businesses due to benefits enjoyed if proper stock management is carried out. Laporan stock opname excel download.Download Format Stock Opname Excel. 6262019 0 Comments Download excel Inventory laporan gudang barang xls Download contoh Inventory barang berbentuk file excel dilengkapi statu barang lokasi penyimpanan dan lain-lain file ini cocok untuk memilah stok gudang maupun persediaan barang yang ada digudang sehingga memudahkan admin untuk.

Stock Opname Perpustakaan

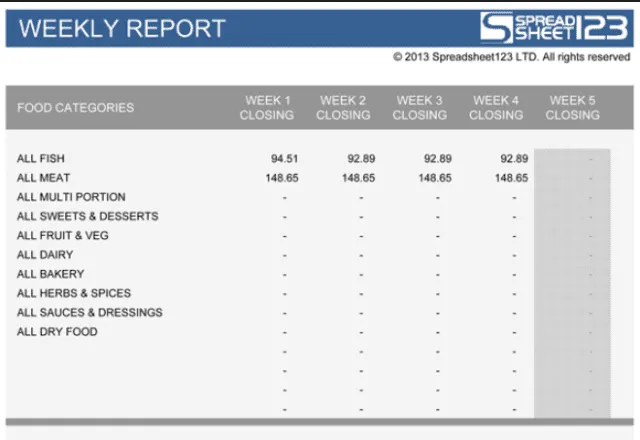

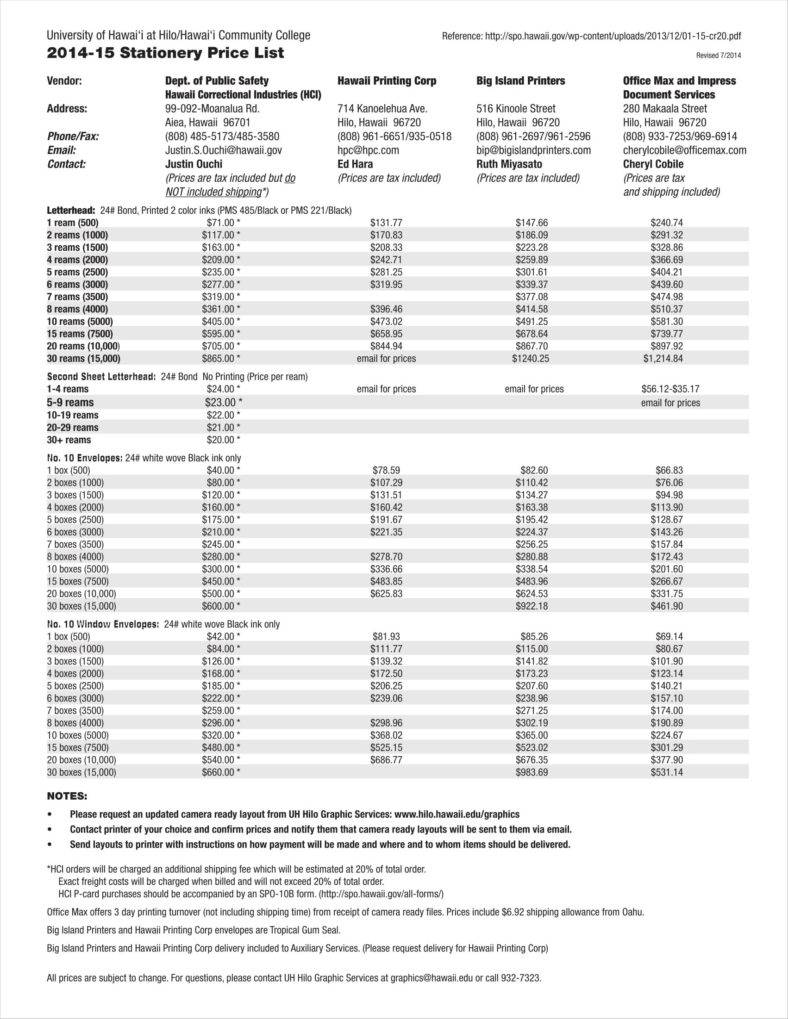

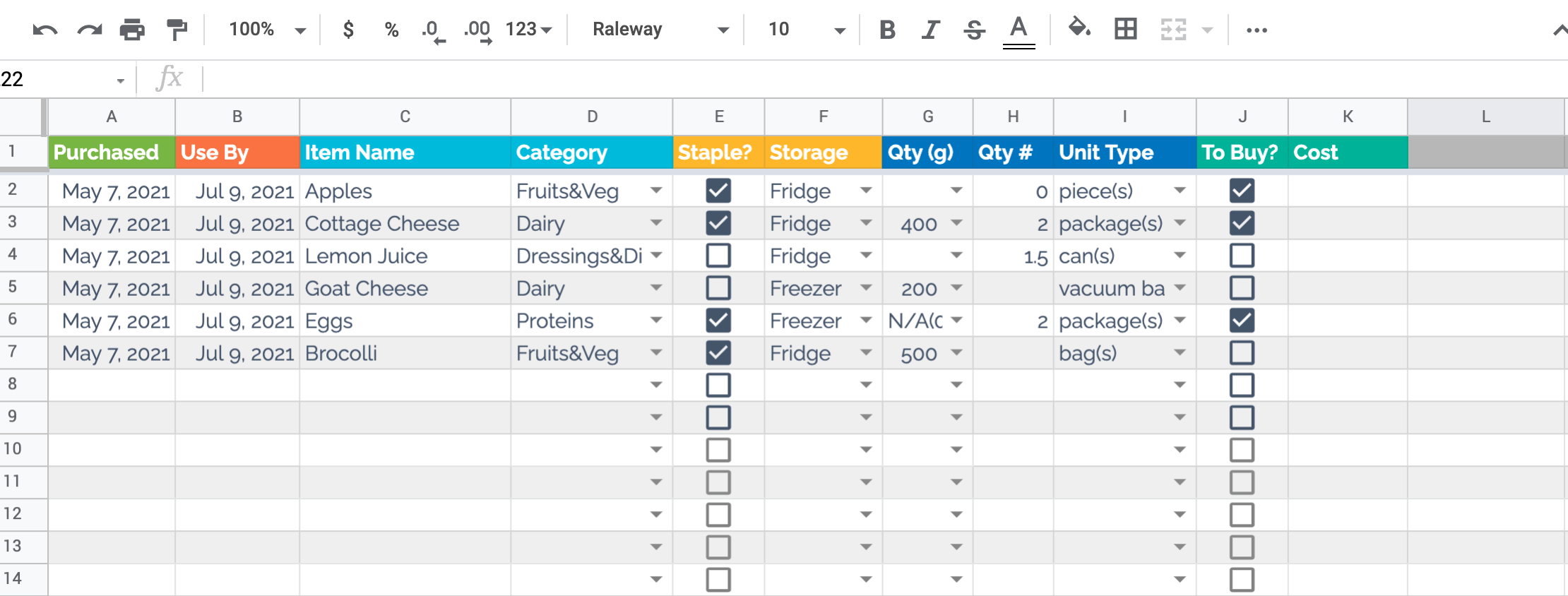

This article provides details of Excel template for inventory management that you can download now.

With these stock management models in Excel format, you can easily manage and manage your stock reserves.

These Excel inventory management examples contain several functions that are necessary already included, so that you can directly adapt them to your system.

Microsoft Excel software under a Windows environment is required to use this template

These Excel templates for inventory management work on all versions of Excel since 2007.

Examples of a ready-to-use spreadsheet: Download this table in Excel (.xls) format, and complete it with your specific information.

To be able to use these models correctly, you must first activate the macros at startup.

The file to download presents four Excel templates for inventory management

Inventory management is the process of monitoring and controlling inventory level and ensuring adequate replenishment in order to meet customer demand. Determining the appropriate inventory level is crucial since inventory ties up money and affects performance. Having too much inventory reduces the working capital and impacts the company’s liquidity. On the contrary, having too little inventory leads to stock outs and missed sales which leads to less profit. It becomes clear that management attention should be focused on keeping inventory level somewhere in between, striving for increased customer satisfaction and minimum stock outs while keeping inventory costs as low as possible.

Service Level

The Service Level (SL) is an important performance indicator which in a simplified manner, measures a company’s ability to service customer demand and is expressed as a percentage. In inventory management, service level is the probability that the customer demand is met or that the customer demand does not exceed the inventory. A service level of 95% means that there is 95% probability that demand will be met and customer orders will be fulfilled on time, while the probability that a stock out will occur, resulting in missed sales, is 5%.The higher the Service Level, the higher the customer satisfaction but also the higher the inventory level. Since the future demand is uncertain, achieving a 100% Service Level would require an infinite amount of inventory which is clearly unachievable. Management should understand the trade-off between the cost of inventory and the cost of stock-outs and position against inventory levels based on specific criteria.

Inventory Classification

ABC inventory classification is a very popular inventory control technique that follows the Pareto Principle which states that, for many events, roughly 80% of the effects come from 20% of the causes. In a case of a business, it could be stated that roughly the 20% of the end products generates the 80% of the income. In ABC analysis, a company reviews its inventory and sorts all items into three categories, called 'A' items, 'B' items and 'C' items. A typical breakdown would possibly describe “A” items as those that produce 70% of income, “B” items as those that produce 25% of income and “C” items, as those that produce 5% of income. This classification might be different from company to company but managers should be able to find the pattern that suits best their needs. Clearly, “A” items require closer attention and should be handled differently. Assigning higher Service Levels for those items is a wise choice. The higher service level will lead to higher inventory but will also decrease the probability of a stock out. A 5% probability of a stock out for an “A” item will result to much higher losses than of a 5% probability for a “C” item. A 99% Service Level for an “A” item could have about the same impact as an 85% Service Level for a “C” item and managers should position against each category accordingly.

Forecast Error and Safety Stock

It has been already stated, that customer demand is uncertain. Managers should try to predict future demand based on statistical data and taking into account multiple criteria. It is highly desirable to try to predict the future demand and get properly prepared even with a certain degree of uncertainty than having no expectation of what is about to happen. The methods and tools used for forecasting are not under the scope of this paper. What is really important, is to find a way to calculate how closely the prediction of the demand meets the actual demand, thus how accurate a forecast is. The difference between the actual and the forecasted data is the Forecast Error. Since the Forecast Error can be calculated and not just predicted, it can be quite a safe driver for inventory management. The goal is to keep just as much inventory as it is really needed and by knowing that there is a fixed error in our estimation, we can safely take it into account and add up a bit of extra stock to our inventory to compensate for this misalignment. This is called Safety Stock and its purpose of existence is to absorb the error of the estimation and to protect the company against an unexpected and unwanted stock out. In a simplified scenario, a 30% variation of the forecasted demand should result in a 30% increase of the inventory level.

Download Format Stock Opname Excel 2018

Root Mean Square Error (RMSE)

Download Format Stock Opname Excel File

In order to calculate the errorof a forecast the RMSE method is preferred among others, as it calculates the standard deviation of the residuals between the actual and the forecasted data. As the name suggests, the difference between the forecasted demand and the actual demand is squared and then it is expressed as the square root of the average squared residuals. In the table below, real data are presented.